30%

of manufacturers have mature digital transformation, with significant growth potential.

20%

improvements in productivity and operational efficiency are achievable for manufacturers adopting digital transformation.

30%

reduction in maintenance costs and downtime: that’s the result reported by 60% of manufacturers using AI for predictive maintenance.

Lead the Future of Manufacturing with Strategic Transformation

We offer tailored solutions to meet the unique challenges of the manufacturing industry. Our strategic approach empowers manufacturers to lead through digitalization, AI integration, and digital capability development, enhancing operational efficiency, productivity, and innovation.

JOIN THOUSANDS OF PIONEERS...

How We Help Manufacturing Companies

AI-Powered Predictive Maintenance and Automation

Guide manufacturers in selecting and implementing AI solutions to enhance predictive maintenance, automate repetitive tasks, and optimize production efficiency.

Digital Strategy and Operational Excellence

Collaborate to design strategic digital roadmaps that optimize production processes, enhance supply chain integration, and improve resource allocation. Align digital initiatives with business goals to achieve strategic impact and efficiency.

Sustainability and Operational Efficiency

Help manufacturers integrate sustainable practices into production and supply chain operations, enhancing ESG reporting and reducing environmental impact.

Workforce Digital Capability Development

Provide strategic guidance on upskilling manufacturing teams to effectively use digital tools, data analytics, and AI technologies, fostering a culture of agility and continuous improvement.

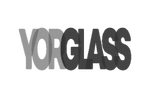

Figure 1: Digital Maturity Index (DMI) Study Results:

Manufacturing Industry Score, Averages, Leaders, and Laggards

Digital Maturity Index of Manufacturing Industry

While digital transformation is essential, progress has stagnated, and industry disparities are growing. This year’s benchmark reveals:

- Slower transformation – The industry’s average maturity score barely changed, signaling a loss of momentum.

- The gap is widening – Leaders score 3.87, while laggards remain at 1.80, showing a growing divide in digital capabilities.

- Three key differentiators – Leaders excel in operational efficiency, workforce development, and AI-driven technologies, setting them apart in a competitive market.

The findings are clear: companies that prioritize AI, automation, and workforce upskilling will lead the future of manufacturing.

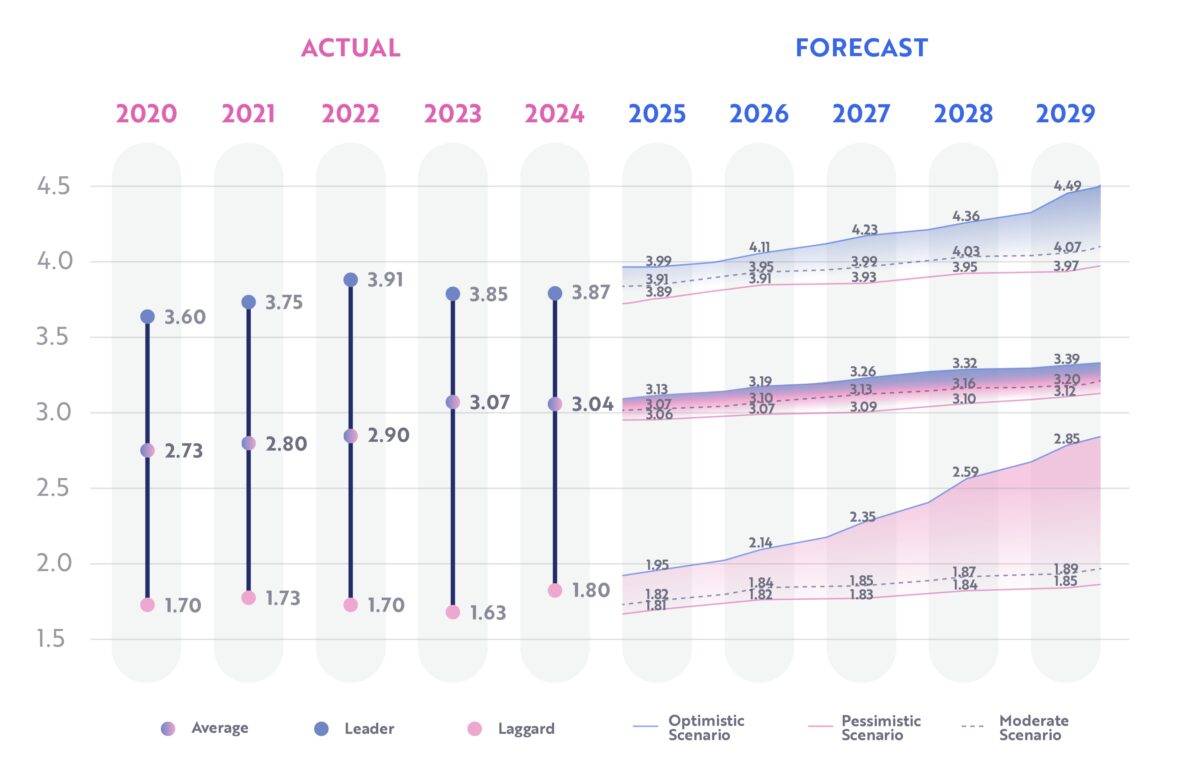

Figure 1: Manufacturing Industry DMI Evolution (2020–2029) with Scenario-Based Forecasts

Leader, Average, and Laggard Trajectories under Optimistic, Moderate, and Pessimistic Projections

Future 2030: Manufacturing Industry Outlook

A digital renaissance is transforming manufacturing. Are you ready to lead?

Explore how digital maturity is reshaping factories, operations, and strategies, and learn what separates future-ready manufacturers from the rest.

Includes:

- Benchmark data from 2020–2024

- Key imperatives: AI-first mindset, operational excellence, workforce upskilling

- Five predictions defining manufacturing by 2030

Key Technologies Transforming

the Industry

As manufacturers face increasing pressure to improve quality, reduce costs, and meet evolving customer demands, digital transformation has become a critical enabler of success. Explore how digital technologies are reshaping the manufacturing industry and gain strategic insights for executives seeking to achieve digital excellence in manufacturing industry.

Frequently Asked Questions

Transformation in manufacturing involves integrating digital technologies, AI strategies, and sustainable practices into production processes, supply chains, and operations to enhance efficiency, agility, and growth.

It enables manufacturers to remain competitive, optimize operations, reduce costs, enhance product quality, and achieve sustainability goals in an evolving global market.

- Optimize Operations and Production Efficiency: Utilize advanced digital tools and AI-driven analytics to enhance shop-floor optimization, supply chain integration, and real-time decision-making.

- Decisive Strategic Planning: Invest in scalable digital infrastructures and prioritize high-impact initiatives that offer substantial ROI and operational agility.

- Cultivate a Culture of Innovation: Promote a digital-first mindset, continuous learning, and cross-functional collaboration to foster innovation and adaptability.

Common challenges include legacy systems, skills shortages, cultural resistance, and integration complexities with existing production systems.

AI enhances predictive maintenance, automates repetitive tasks, optimizes production processes, and improves decision-making through real-time analytics and data-driven insights.

By adopting energy-efficient production methods, responsible sourcing, and transparent ESG reporting, fostering sustainable growth and compliance.

It empowers employees to effectively leverage digital tools and AI technologies, enhancing productivity, operational agility, and innovation.

Through integrated digital platforms, real-time analytics, and predictive supply chain management powered by AI.

Conduct a digital maturity assessment, define clear objectives, and develop a strategic roadmap aligned with business goals and market demands.

Transform Your Manufacturing Operations Today

Contact us to learn how to lead the manufacturing industry with strategic digital transformation, AI integration, sustainability, and digital capability development.