In today’s fast-paced world, speed is a crucial metric of success across all facets of manufacturing. From product development to market delivery, the ability to act swiftly and efficiently dictates a company’s capacity to compete and thrive. Digital transformation is the catalyst that empowers manufacturers to meet these challenges head-on, transforming not just the speed but the very nature of their operations.

Accelerating Time to Market

Digital technologies such as additive manufacturing (3D printing), digital twins, and advanced simulation software have revolutionized the product development process. These tools enable rapid prototyping, allowing manufacturers to iterate and refine products in a fraction of the time traditionally required. The result is a significant acceleration in time to market, enabling companies to seize opportunities and capture value more quickly.

Enhancing Responsiveness to Customer and Market Demands

AI, machine learning, and data analytics provide manufacturers with real-time insights into customer behavior and market trends. This information allows companies to adapt their product offerings and marketing strategies with agility, responding to emerging demands before their competitors. Furthermore, digital platforms facilitate direct engagement with customers, enabling personalized experiences and fostering loyalty.

Rapid Reaction to Production Issues

IoT technologies and predictive analytics have transformed the manufacturing floor, enabling real-time monitoring of equipment and processes. This visibility allows for the immediate identification and rectification of production issues, minimizing downtime and maintaining uninterrupted operations. Moreover, predictive maintenance can anticipate and prevent potential failures, ensuring that production lines run smoothly and efficiently.

Predicting and Mitigating Supply Chain Disruptions

The global nature of modern supply chains introduces a multitude of risks, from geopolitical tensions to natural disasters. Digital tools empower manufacturers to build resilient supply chains, capable of withstanding and quickly recovering from disruptions. Advanced analytics and AI provide foresight into potential disruptions, while blockchain technology ensures transparency and trust among supply chain partners, facilitating rapid coordination and response.

Building Resilience with Agility

Ultimately, the speed afforded by digital transformation is about more than just efficiency; it’s about building a resilient organization. Digital capabilities enable manufacturers to adapt to changes, overcome challenges, and capitalize on opportunities with a speed and precision previously unimaginable. This agility is the cornerstone of resilience, ensuring that companies can not only survive but thrive in the face of uncertainty.

Navigating Speed with Precision: The Role of the Digital Maturity Index (DMI)

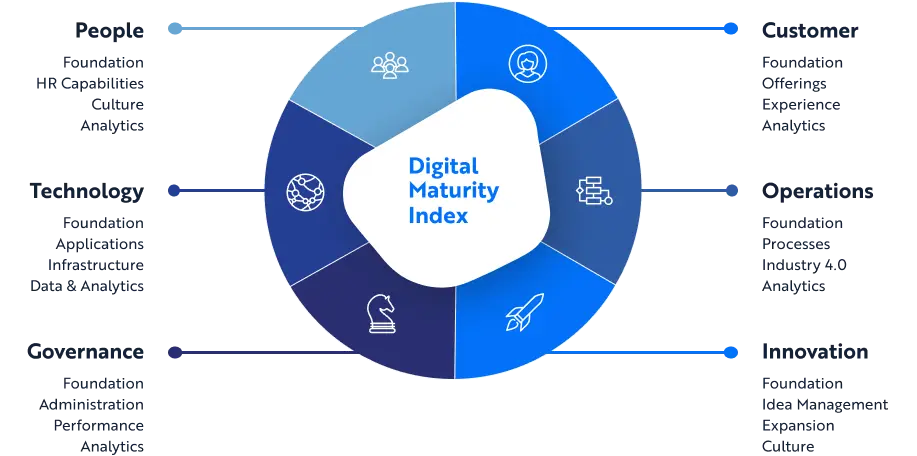

In the quest for speed in manufacturing, knowing where to focus your digital transformation efforts can be as crucial as the transformation itself. The Digital Maturity Index (DMI) emerges as an indispensable tool in this context, offering a comprehensive assessment of a company’s digital capabilities and providing a roadmap for prioritization and improvement. By measuring and benchmarking digital maturity regularly, manufacturers can gain the strategic edge necessary for making informed decisions and ensuring that their efforts in digital acceleration yield tangible results.

Assessing and Prioritizing Digital Initiatives

The DMI allows manufacturers to take a holistic view of their current digital landscape, assessing capabilities across various domains such as automation, data analytics, digital product development, and supply chain integration. This assessment helps identify both strengths to build upon and gaps that require attention, ensuring that investments in digital technologies are aligned with the areas that will most significantly impact speed and agility.

Benchmarking for Competitive Advantage

Continuous measurement and benchmarking against industry standards and competitors play a pivotal role in maintaining a strategic edge. The DMI enables manufacturers to track their progress over time, providing insights into how improvements in digital maturity correlate with enhanced operational speed. This ongoing evaluation ensures that companies not only keep pace with but also outperform their peers, securing a dominant position in the market.

Driving Action Where It Matters

The adage “what’s measured gets done” holds particularly true in the context of digital transformation. The DMI focuses attention on actionable insights and prioritized initiatives, driving efforts towards areas that will most significantly enhance speed across the manufacturing process. Whether it’s reducing time to market through digital product development tools, improving responsiveness with data analytics, or ensuring rapid reaction to production issues through IoT technologies, the DMI guides manufacturers in deploying their resources where they will have the maximum impact.

Case Study: A Manufacturer’s Journey to Light-Speed Operations

Consider a manufacturing company that leveraged the DMI to pinpoint a critical gap in its supply chain visibility and responsiveness. By prioritizing investments in blockchain technology and advanced analytics, the company was able to significantly enhance its supply chain agility, reducing response times to disruptions from weeks to hours. This strategic focus, guided by insights from the DMI, not only improved operational efficiency but also strengthened the company’s market position by enabling a level of customer responsiveness previously unattainable.

Conclusion: The Strategic Imperative of Measuring Digital Maturity

As manufacturers navigate the complexities of digital transformation, the Digital Maturity Index (DMI) serves as both a compass and a catalyst for accelerating speed across all facets of operations. By offering a structured approach to assessing, prioritizing, and benchmarking digital capabilities, the DMI empowers manufacturers to strategically advance their digital maturity. In doing so, they not only achieve operational efficiencies and market responsiveness at light-speed but also ensure sustained competitive advantage in an increasingly dynamic and fast-paced manufacturing landscape. The journey towards digital acceleration is continuous, and with the DMI, manufacturers are equipped to navigate this journey with precision and strategic insight.

For manufacturers, the journey towards digital transformation is not merely a technological upgrade but a strategic imperative to harness speed as a defining characteristic of their operations. In a marketplace where speed can dictate success or failure, digital technologies offer the tools to navigate the future with confidence. By embracing digital transformation, manufacturers can achieve light-speed operations, positioning themselves at the forefront of innovation, responsiveness, and resilience. The race is on, and in this new era of manufacturing, speed is the ultimate prize.