In an era where global competition intensifies by the day, technological advancements evolve at breakneck speed, and consumer demands shift with unprecedented agility, manufacturing firms find themselves at a critical juncture. Operational excellence has transitioned from a strategic advantage to an absolute necessity. It’s the cornerstone upon which companies can build sustainable growth, adapt to market changes, and secure their position in the future of manufacturing.

The Pillars of Operational Excellence

Operational excellence in manufacturing is underpinned by several key pillars: process efficiency, quality control, flexibility, and innovation. Each of these elements plays a crucial role in creating a lean, responsive, and resilient operation.

Process Efficiency: Streamlining operations to eliminate waste, reduce lead times, and optimize resource utilization.

Quality Control: Implementing rigorous standards to ensure product consistency and reliability, fostering customer trust and loyalty.

Flexibility: The ability to quickly adapt to market changes and customer needs, enabling customization and rapid response to demands.

Innovation: Continual investment in new technologies and methodologies to improve products, processes, and business models.

Leveraging Technology for Enhanced Operations

The journey to operational excellence is intrinsically linked with digital transformation. Emerging technologies like the Internet of Things (IoT), Artificial Intelligence (AI), and machine learning are revolutionizing the manufacturing landscape, enabling companies to achieve unprecedented levels of efficiency, quality, and flexibility.

Case Study: General Electric’s Digital Transformation

General Electric (GE) stands as a testament to the transformative power of digital technology in manufacturing. Faced with the challenge of modernizing its operations, GE embraced the Industrial Internet of Things (IIoT) to connect machines, data, and people in real-time. By implementing its Predix platform, GE was able to monitor equipment health, predict maintenance needs, and optimize performance across its operations. This digital transformation not only improved efficiency and reduced downtime but also unlocked new revenue streams through innovative service offerings.

Cultural Transformation: A Mindset for Excellence

Operational excellence extends beyond technology and processes; it requires a cultural shift within the organization. Cultivating a culture of continuous improvement, where every employee is empowered to suggest and implement changes, is critical. This mindset fosters an environment where innovation thrives, and operational challenges are addressed proactively.

Leadership’s Role in Cultural Transformation

Leadership must champion this cultural shift, demonstrating a commitment to operational excellence and setting the tone for the organization. By prioritizing transparency, encouraging collaboration, and rewarding initiative, leaders can cultivate a culture that embraces change and strives for excellence.

Navigating the Path to Operational Excellence

The path to operational excellence is iterative and unique to each organization. However, the journey typically involves:

Assessment: Evaluating current operations to identify inefficiencies, bottlenecks, and opportunities for improvement.

Strategy Development: Crafting a tailored plan that aligns with the company’s goals, leveraging technology, and fostering a culture of excellence.

Implementation: Executing the strategy with a focus on quick wins and scalable solutions, supported by continuous monitoring and adjustment.

Sustainability: Ensuring long-term success by embedding operational excellence into the company’s DNA, through ongoing training, leadership development, and innovation initiatives.

Case Study: Siemens’ Digital Factory

Siemens’ Digital Factory division offers a compelling example of operational excellence in action. By integrating digital technologies with its manufacturing operations, Siemens achieved a level of automation and flexibility that set new industry standards. Its Amberg Electronics Plant, renowned for its high level of digitalization, operates with a remarkable 99.99885% quality rate. This success is attributed to a combination of advanced robotics, AI-driven analytics, and a workforce skilled in digital technologies. Siemens’ journey underscores the importance of embracing digital transformation to drive operational excellence.

Conclusion: A Strategic Imperative

In the fast-paced world of manufacturing, operational excellence is not just a goal but a strategic imperative. It’s the foundation upon which companies can build a competitive advantage, respond to challenges, and secure their future. By focusing on the pillars of operational excellence, leveraging digital technologies, and fostering a culture of continuous improvement, manufacturers can navigate the complexities of the modern marketplace with confidence and agility.

As we continue to explore the various facets of operational excellence in this blog series, remember that the journey is ongoing. The landscape of manufacturing is ever-evolving, and so too must our approaches to achieving and sustaining excellence. Let’s embrace this journey together, sharing insights, challenges, and successes along the way.

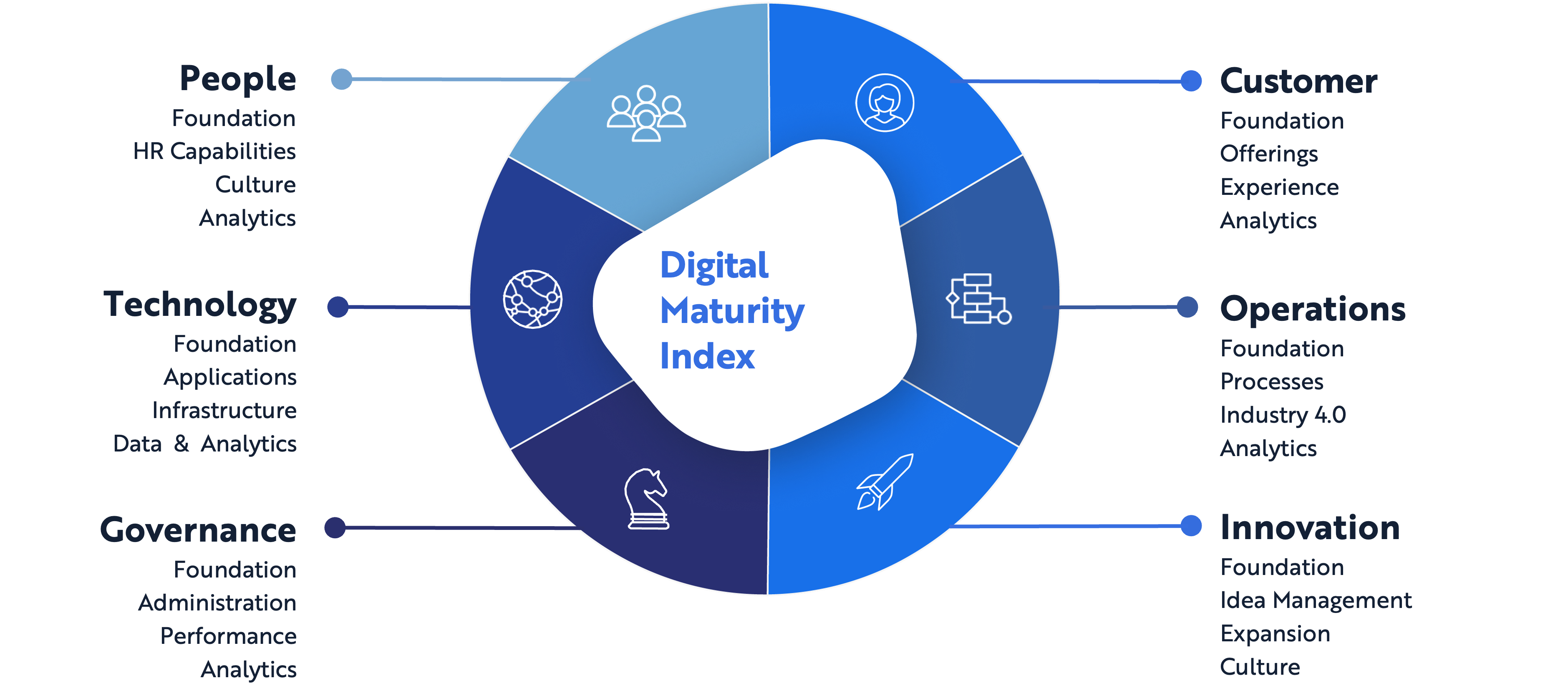

Measuring Progress: The Role of Digital Maturity Index (DMI)

A critical component of achieving operational excellence is the ability to measure and benchmark progress. This is where the concept of a Digital Maturity Index (DMI) becomes invaluable. The DMI offers companies a comprehensive framework to assess their current level of digital maturity, providing a clear snapshot of where they stand on their digital transformation journey.

Why Measurement Matters

In the pursuit of operational excellence, “what’s measured gets done.” Measurement allows organizations to:

Identify Strengths and Weaknesses: Understand which areas of digital transformation are thriving and which require further development.

Benchmark Against Industry Standards: Compare digital maturity levels with peers and competitors, gaining insights into industry best practices.

Set Targeted Goals: Establish clear, measurable objectives for digital initiatives, ensuring alignment with broader operational excellence strategies.

Track Progress Over Time: Monitor advancements in digital maturity, enabling companies to adjust their strategies in response to changing dynamics and new opportunities.

How the Digital Maturity Index Works

The DMI typically evaluates several dimensions of digital maturity, including technology adoption, data analytics capabilities, digital culture, customer experience, and digital innovation. By assessing these areas, companies can pinpoint specific aspects of their digital strategy that need enhancement.

Incorporating DMI into Your Strategy

Integrating the Digital Maturity Index into your operational excellence strategy involves several key steps:

Assessment: Conduct a comprehensive evaluation using the DMI to establish your baseline digital maturity level.

Gap Analysis: Analyze the results to identify gaps between your current state and desired outcomes.

Action Planning: Develop targeted initiatives to address identified gaps, leveraging insights from the DMI to prioritize efforts.

Continuous Improvement: Use the DMI periodically to reassess your digital maturity, ensuring continuous improvement and adaptation to digital trends.

Leveraging DMI for Operational Excellence

The journey to operational excellence is markedly enhanced by a clear understanding of your digital maturity. For instance, Siemens and General Electric, through continuous measurement and benchmarking, have been able to strategically focus their digital transformation efforts, resulting in significant improvements in operational efficiency and innovation. By adopting a similar approach and utilizing tools like the Digital Maturity Index, companies can ensure their digital transformation initiatives are both effective and aligned with their overall strategic goals.

Conclusion: The Path Forward

Measuring digital maturity is not just about understanding where you are today; it’s about charting a path forward towards operational excellence. As we delve deeper into the elements that define operational excellence in this blog series, remember that the journey is iterative and requires constant measurement and adaptation. The Digital Maturity Index serves as a compass on this journey, guiding companies through the complexities of digital transformation with clarity and purpose.