The digital revolution in manufacturing, characterized by the adoption of technologies such as the Internet of Things (IoT), Artificial Intelligence (AI), Machine Learning (ML), and advanced analytics, is at the heart of this new era of precision. These technologies are not just tools but catalysts for a paradigm shift, enabling companies to achieve levels of accuracy, efficiency, and insight previously unattainable.

Precision in Quality

Digital technologies facilitate real-time monitoring and quality control across the manufacturing process, allowing for immediate adjustments and reducing the margin for error to near zero. IoT sensors and AI algorithms work in tandem to predict and prevent defects before they occur, ensuring that every product meets the highest standards of quality.

Precision in Decision-Making

Data analytics and AI transform vast amounts of data into actionable insights, enabling precise decision-making. From strategic planning to operational tweaks, the ability to analyze and act on data with pinpoint accuracy means that decisions are no longer based on gut feelings or historical trends but on real-time information and predictive analytics.

Precision in Manufacturing Processes

Digital twins — virtual replicas of physical systems — allow manufacturers to simulate and optimize their processes in a digital realm. This precision in planning and execution leads to reduced waste, improved efficiency, and the ability to swiftly adapt to changes in demand or production parameters.

Precision in Planning and Pricing

Advanced analytics and AI-driven tools enable manufacturers to forecast demand with greater accuracy, plan their production schedules accordingly, and set prices that reflect the current market dynamics and cost inputs. This precision in forecasting and pricing not only maximizes profitability but also enhances competitiveness.

Precision in Products and Procurement

Customization and personalization are becoming key differentiators in the marketplace. Digital capabilities allow for the precise tailoring of products to individual customer specifications, while also optimizing procurement processes to ensure the timely and cost-effective sourcing of materials.

The Competitive Edge: Surviving and Thriving in a Winner-Takes-All Market

In a market that increasingly favors precision, companies that advance their digital capabilities are setting a new standard of excellence. This digital transformation is not just about keeping pace; it’s about setting the pace, defining the competitive landscape, and, in some cases, reshaping the industry itself.

The Winners

Companies that embrace digital transformation and leverage it to enhance precision across their operations are likely to experience significant advantages:

- Increased market share due to higher quality products and services that meet customer needs more effectively.

- Improved profitability through optimized processes, reduced waste, and dynamic pricing strategies.

- Greater agility in responding to market changes and customer demands.

The Challengers

For those lagging in digital adoption, the path forward is daunting. The gap between them and the leaders is not just widening; it’s deepening. Catching up requires not only significant investment in technology but also a cultural shift towards innovation, data-driven decision-making, and continuous improvement.

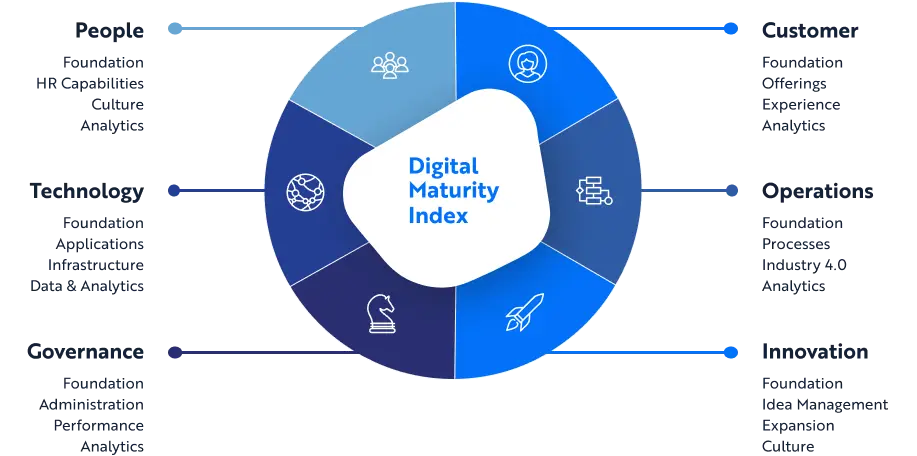

Enhancing Precision Through Digital Maturity: The Role of the DMI

In the context of leveraging digital capabilities for precision in manufacturing, the Digital Maturity Index (DMI) serves as a crucial tool for assessing, guiding, and benchmarking a company’s digital transformation efforts. The DMI not only measures the current state of digital adoption within an organization but also provides a roadmap for advancing those capabilities to achieve greater precision.

Assessing Digital Capabilities for Precision

The DMI evaluates a range of dimensions critical to manufacturing precision, including data analytics, IoT integration, AI and ML adoption, and digital process automation. By assessing these areas, companies can identify gaps in their digital infrastructure that, if addressed, could significantly enhance precision in quality control, decision-making, manufacturing processes, and beyond.

Guiding Investment in Digital Transformation

One of the key benefits of the DMI is its ability to highlight specific areas where investment in digital technologies can yield the most significant improvements in precision. This targeted approach ensures that resources are allocated effectively, maximizing the impact of digital transformation initiatives on operational precision.

Benchmarking Progress Towards Precision

As companies advance their digital capabilities, the DMI allows them to benchmark their progress not only against their past performance but also against industry standards and competitors. This benchmarking is crucial for understanding how improvements in digital maturity translate into enhanced precision across manufacturing operations.

Case Study: Leveraging DMI for Enhanced Precision

Consider a manufacturer that used the DMI to identify a significant gap in its use of AI for predictive maintenance. By investing in AI technologies and integrating them with its existing IoT infrastructure, the company was able to predict equipment failures with much greater accuracy. This not only reduced downtime but also improved the precision of the manufacturing process, leading to higher quality products and greater customer satisfaction. Over time, the DMI helped the company track its improvements in digital maturity and operational precision, validating its strategic focus on digital transformation.

Driving Competitive Advantage Through Precision

The integration of the Digital Maturity Index into the strategy for enhancing precision underscores the symbiotic relationship between digital transformation and operational excellence. In a manufacturing landscape where precision is a key determinant of success, the DMI offers a structured approach to achieving and sustaining high performance. Companies that use the DMI to guide their digital strategies are better positioned to achieve the level of precision required to outperform peers and thrive in a competitive, winner-takes-all market.

Conclusion: Precision as the Path Forward

The message is clear: in the relentless pursuit of precision, digital capabilities are not just enablers; they are the driving force. As the manufacturing sector evolves, the correlation between digital maturity and competitive advantage becomes increasingly apparent. Companies that recognize this shift and invest in advancing their digital capabilities are the ones that will not only survive but thrive, setting new benchmarks for precision and performance in their industries. In a market where precision dictates success, the race is on, and the winners will take all.